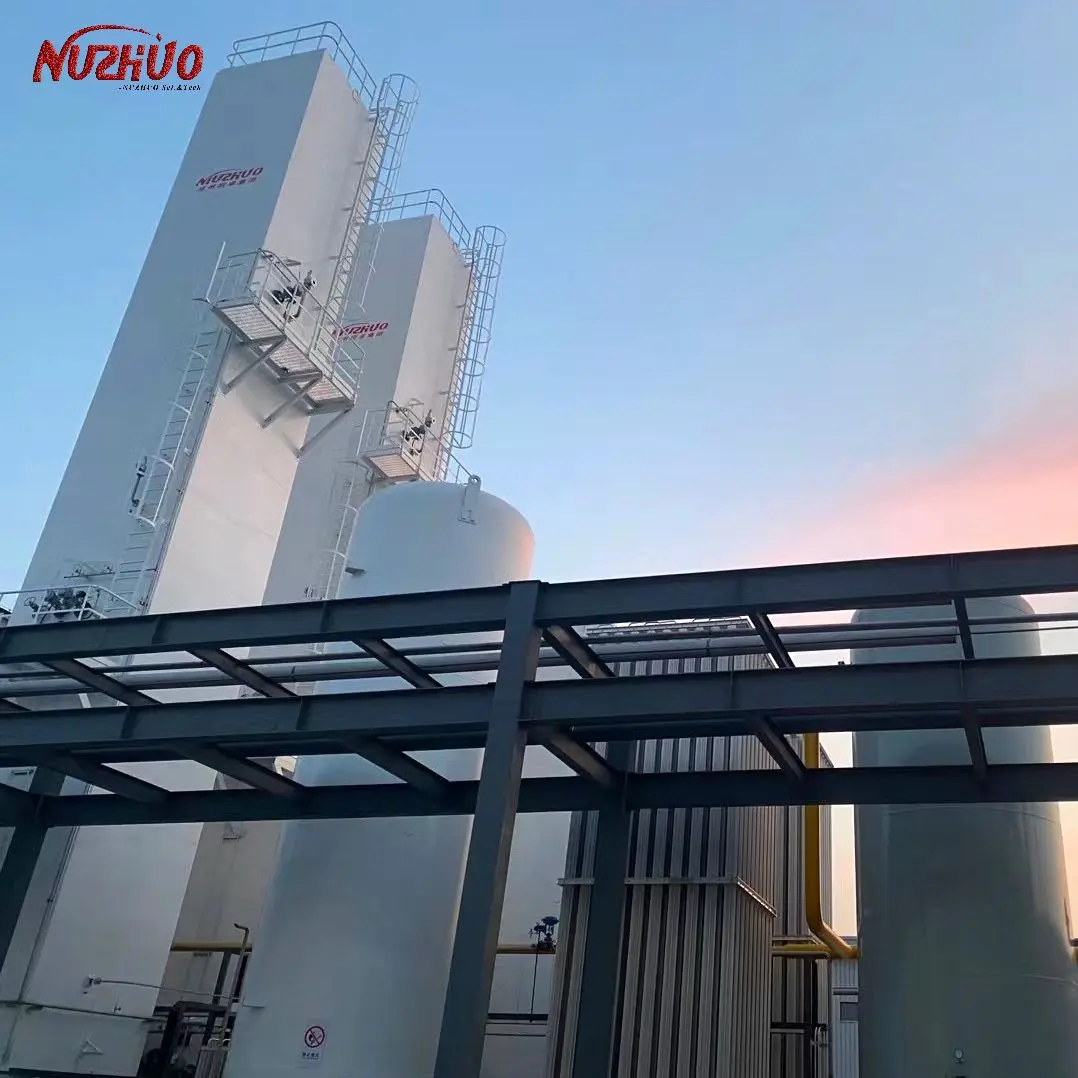

Cold Box System Of the Fractionating Tower The main heat exchanger uses long-plate heat exchanger. The temperature differences at thermal points shall not exceed 30C to minimize the loss of cold amount and power consumption. The cold box structure is reasonable and take up less area. Turbo Expander Use advanced design and process soft wares to design and process performance and the flow passage design. This way, the efficiency of turbo expander will meet the best condition of design parameter to have a better pneumatic performance and flow field. Instrumental Control System 1) Use central control and by-unit site control to ensure an effective inspection on the operation of air separation plant. 2) Use DCS system to enhance the advanced feature and reliability of the plant

Working Principle

Principle of operation of a Cryogenic Air Separation Unit (Cryogenic ASU)

Cryogenic ASU operates on the basis of the boiling points difference of air components and deep cooling to separate air components.

Here's what happens in a nutshell:

1. The atmospheric air is compressed and cleaned (purification from impurities such as dust, water vapor).

2. The clear air is cooled to a very low temperature (cryogenic, ~ -170 ~ -200°C) by heat exchange and expansion.

3. The cold air descends into the distillation column. Due to the different boiling points of nitrogen (-195.8°C), oxygen (-183°C), argon (-185.9°C) and other impurities, they boil off and condense at different levels in the distillation column.

4. The nitrogen (lowest boiling point) rises as a gas, oxygen (higher boiling point) accumulates at the bottom as liquid, and argon is removed from the middle part of the column.

5. The final gaseous and liquid oxygen, nitrogen and argon are collected for industrial use.

Air Separation Technology Plant – separatorunit.com Air separation unit are used in many industrial processes.

The atmosphere is a virtually inexhaustible source of nitrogen and oxygen. Therefore both nitrogen and oxygen are produced by air separation in industry. The most commonly used process is the cryogenic air separation process. In general, the current common process of the cryogenic air separation process is mostly full low pressure double-column rectification separation process.

Hot Tags: Cryogenic Plant Nitrogen Processing Plants, China Cryogenic Plant Nitrogen Processing Plants manufacturers, factory, Argon ASU, Liquid Oxygen Production Plant, Industrial And Medical Liquid Oxygen Plant, Cryogenic Air Separation Unit, 1000M3 H Liquid Nitrogen Production Plant, Liquid Oxygen Production Plant